The Future of Mining: How Predictive Intelligence and Real-Time Data are Revolutionizing the Industry

The mining industry has long been a crucial pillar of the global economy, providing the raw materials that power our modern world. However, as the demand for resources continues to grow, mining companies are facing increasing pressure to optimize their operations, improve safety, and reduce their environmental impact. Fortunately, recent advances in technology are providing a solution to these challenges, particularly in the realm of mine ventilation and cooling systems.

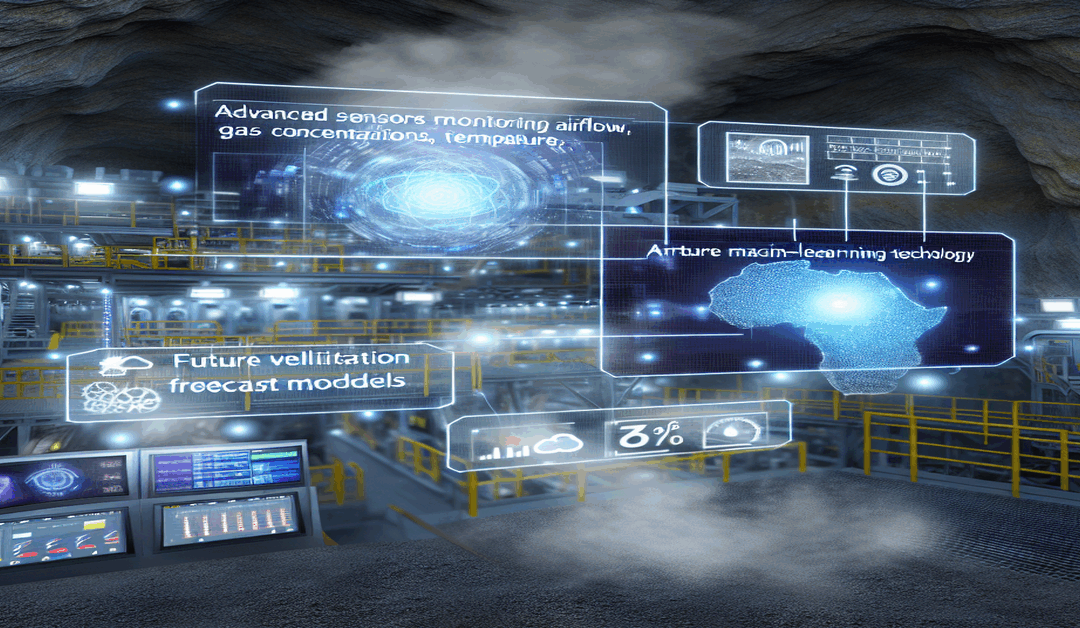

In South Africa, where mining is a major contributor to the economy, the integration of **real-time monitoring** and **predictive intelligence** is transforming the way mines operate. By leveraging sensors, data analytics, Artificial Intelligence (AI), and machine learning, mining companies are now able to continuously track air quality, predict future ventilation needs, and optimize their systems for maximum efficiency and safety.

Real-Time Air Quality Monitoring: A Game-Changer for Mine Safety

One of the most significant benefits of this technological revolution is the ability to monitor air quality in real-time. In the past, miners had to rely on periodic manual readings to assess the conditions in their mines, which often led to delayed responses and potential safety hazards. Today, however, advanced sensors can continuously track a wide range of parameters, including airflow, gas concentrations, temperature, and dust levels[1].

This real-time data enables ventilation systems to quickly adapt to changing conditions, ensuring that miners always have access to a safe and healthy working environment. For example, if a sensor detects a sudden increase in carbon monoxide levels, the ventilation system can automatically increase airflow to the affected area, preventing a potentially deadly buildup of toxic gases.

Predictive Ventilation Control: Simulating the Future for Optimal Performance

While real-time monitoring is crucial for maintaining safety, it’s only half the battle. To truly optimize their ventilation systems, mining companies need to be able to predict future needs and simulate the effects of potential adjustments. This is where predictive intelligence comes into play.

By analyzing vast amounts of historical data, advanced algorithms can create accurate models of a mine’s ventilation requirements. These models take into account a wide range of variables, such as the size and layout of the mine, the type of equipment being used, and even the weather conditions on the surface[1].

Armed with these predictive models, mining companies can now simulate the effects of changes to their ventilation systems before implementing them in the real world. This allows them to identify potential issues and optimize their adjustments for maximum efficiency, all without risking the safety of their workers or the integrity of their operations[1].

The Benefits of Digital Transformation: Efficiency, Safety, and Sustainability

The integration of real-time monitoring and predictive intelligence is already delivering significant benefits to the mining industry. By optimizing airflow and cooling systems, mining companies are able to reduce their energy consumption, lower their operating costs, and minimize their environmental impact[1].

Moreover, the improved safety conditions resulting from these technological advancements are not only protecting the lives of miners but also contributing to a more stable and productive workforce. With fewer accidents and health hazards to worry about, miners can focus on their tasks with greater confidence and efficiency.

Looking ahead, the potential applications of this technology are vast. As more mines embrace the power of real-time data and predictive intelligence, we can expect to see even greater improvements in efficiency, safety, and sustainability. From reducing greenhouse gas emissions to minimizing the risk of catastrophic accidents, the benefits of this digital transformation are clear.

The Way Forward: Embracing Innovation for a Brighter Future

As the mining industry continues to evolve, it is clear that technology will play an increasingly vital role in shaping its future. By embracing innovation and investing in the latest advancements, mining companies can position themselves for success in an ever-changing world.

Of course, this transformation will not happen overnight. It will require a significant investment of time, resources, and expertise to fully realize the potential of real-time monitoring and predictive intelligence. However, for those companies that are willing to take the leap, the rewards are sure to be substantial.

In South Africa and beyond, the mining industry stands at a crossroads. Will it cling to the old ways of doing things, or will it embrace the power of technology to build a brighter, safer, and more sustainable future? The choice is clear, and the time to act is now.

As we move forward, it is important to remember that the success of this digital transformation will depend not only on the technology itself but also on the people who use it. By fostering a culture of innovation, collaboration, and continuous learning, mining companies can ensure that their employees are equipped with the skills and knowledge they need to thrive in this new era.

Ultimately, the integration of real-time monitoring and predictive intelligence represents a major step forward for the mining industry. By harnessing the power of data and AI, we can create a future in which mines are safer, more efficient, and more sustainable than ever before. It is a future that we should all be excited about, and one that we should all be working towards, together.

#MiningInnovation #PredictiveIntelligence #RealTimeData

-> Original article and inspiration provided by ReviewAgent.ai Staff Writer

-> Connect with one of our AI Strategists today at ReviewAgent.ai