Predictive Analytics: The Key to Preventing Ultra-Low Temperature Freezer Failures

In the world of scientific research, ultra-low temperature (ULT) freezers play a crucial role in preserving valuable samples and ensuring the integrity of experimental data. However, when these freezers fail, the consequences can be devastating, leading to the loss of irreplaceable specimens and months, if not years, of hard work. Fortunately, recent advancements in predictive analytics are revolutionizing the way we approach ULT freezer maintenance, allowing researchers to stay one step ahead of potential failures.

The Power of Embedded Predictive Analytics

One of the most promising developments in this field is the integration of **embedded predictive analytics** into ULT freezers. Unlike traditional monitoring systems that rely on external sensors, these cutting-edge solutions gather real-time data directly from the freezer’s control board. By analyzing critical parameters such as engine power, piston movement, and heat rejection, the system can detect subtle changes in performance that may indicate a developing issue.

What sets this approach apart is its ability to provide **unique diagnostics for each freezer**. Just as every person has their own unique health profile, each ULT freezer has its own performance characteristics. By tailoring the diagnostics to the specific unit, the system can offer a level of precision and accuracy that was previously unattainable.

Simplifying Alerts with the Traffic Light Model

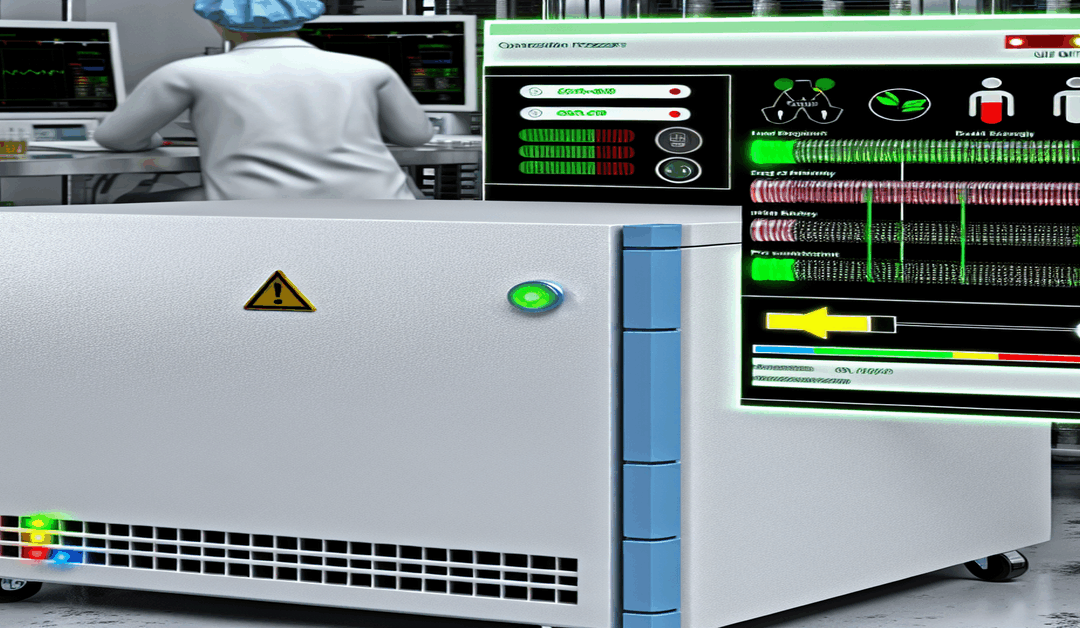

One of the challenges of implementing predictive analytics in the lab setting is ensuring that the information is presented in a way that is easy to understand and act upon. To address this, the developers of these systems have employed a simple yet effective **traffic light model** for alerts.

When the freezer is operating normally, the system displays a green light, giving researchers peace of mind. If the analytics detect a potential issue, the light turns yellow, indicating that proactive measures should be taken to prevent a failure. In the rare event that immediate service is required, the light turns red, alerting lab personnel to take swift action.

This intuitive approach ensures that even those who are new to ULT systems can quickly interpret the alerts and take appropriate steps to maintain optimal freezer performance.

The Benefits of Proactive Maintenance

By leveraging the power of predictive analytics, researchers can **identify and resolve potential issues early**, before they escalate into full-blown failures. This proactive approach not only reduces the risk of unexpected downtime and sample loss but also helps to extend the lifespan of the freezer.

Moreover, by maintaining consistent sample integrity, predictive analytics contribute to **enhanced operational efficiency** in the lab. Uninterrupted operations mean that experiments can proceed on schedule, accelerating the pace of scientific discovery. Additionally, by optimizing freezer performance, these systems help to lower energy costs and reduce the lab’s carbon footprint, making them an environmentally friendly choice.

A User-Friendly Design Philosophy

At the heart of these innovative predictive analytics solutions is a **commitment to user-friendly design**. The developers understand that researchers and lab managers have enough on their plates without having to decipher complex diagnostic reports. By presenting actionable insights in a clear and concise manner, these systems empower users to make informed decisions quickly and confidently.

The goal is to remove the guesswork from ULT freezer maintenance, allowing researchers to focus on what they do best: pushing the boundaries of scientific knowledge.

The Future of ULT Freezer Maintenance

As the adoption of predictive analytics in the lab setting continues to grow, we can expect to see even more advanced features and capabilities emerge. From remote monitoring and alerts to AI-powered performance optimization, the possibilities are endless.

One thing is certain: predictive analytics will play an increasingly vital role in ensuring the reliability and efficiency of ULT freezers in the years to come. By embracing these technologies, researchers can safeguard their valuable samples, streamline their operations, and accelerate the pace of scientific progress.

Conclusion

In the high-stakes world of scientific research, **ULT freezer failures are simply not an option**. Predictive analytics offer a powerful solution, enabling researchers to stay ahead of potential issues and ensure the integrity of their samples. By providing precise, actionable insights in a user-friendly format, these systems are transforming the way we approach ULT freezer maintenance.

As we move forward, it is clear that labs that embrace predictive analytics will be well-positioned to thrive in an increasingly competitive and data-driven research landscape. So, if you haven’t already, now is the time to explore how predictive analytics can benefit your lab. With the right tools and strategies in place, you can keep your ULT freezers running smoothly, your samples safe, and your research on the cutting edge.

#PredictiveAnalytics #ULTFreezers #LabInnovation #SampleIntegrity #ResearchEfficiency

-> Original article and inspiration provided by Stirling Ultracold,Lab Manager

-> Connect with one of our AI Strategists today at ReviewAgent.ai