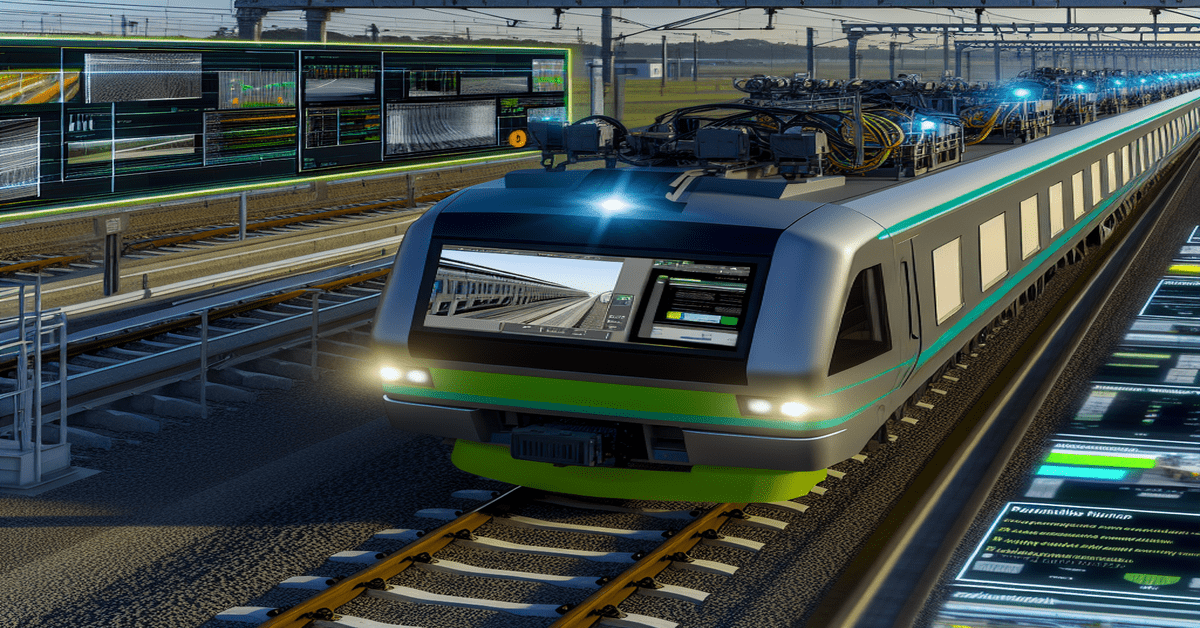

Revolutionizing Rail Safety and Efficiency: The Power of Automated Predictive Inspection

In the fast-paced world of rail transportation, ensuring the safety and reliability of tracks and assets is of utmost importance. Traditional manual inspection methods, while essential, often come with limitations such as time constraints, human error, and operational disruptions. However, the advent of automation in predictive rail inspection is transforming the industry, offering a new era of enhanced efficiency, improved safety, and optimized costs.

The Efficiency and Speed Advantage

One of the most significant benefits of automated rail inspection is the ability to conduct inspections more frequently and rapidly. Automated systems can detect track faults and asset issues quickly and accurately, without the need for lengthy manual inspections that disrupt train operations [2][3]. This increased efficiency allows for timely identification of potential problems, reducing downtime and enabling proactive maintenance. By leveraging automation, rail companies can optimize their asset management strategies, predicting when maintenance is needed rather than relying on reactive or scheduled repairs.

Elevating Rail Safety Standards

Automated rail inspection technologies play a crucial role in enhancing overall rail safety. These intelligent systems can detect a wide range of issues, including track misalignments, missing parts, and wheel defects, at an early stage [3]. By identifying potential hazards before they escalate, automated inspections help prevent accidents and ensure the safe operation of trains. The early detection capabilities of automation contribute to a proactive safety approach, minimizing risks and promoting a culture of continuous improvement in rail safety standards.

Optimizing Costs through Predictive Maintenance

In addition to efficiency and safety benefits, automation in rail inspection offers significant cost optimization opportunities. By enabling predictive maintenance, automated systems minimize the need for unnecessary manual inspections and reduce resource utilization [2][3]. Rail companies can allocate their budgets more effectively, focusing on targeted maintenance interventions based on data-driven insights. The vast amount of data generated by automated inspections can be analyzed to identify trends and forecast potential failures, enabling smarter investment decisions in maintenance activities. This predictive approach ultimately leads to lower operational costs and improved asset lifecycle management.

The Power of Predictive Analytics

Automation in rail inspection goes beyond simple data collection; it unlocks the potential of predictive analytics. The large volumes of data generated by automated systems can be analyzed to uncover patterns, trends, and insights that were previously difficult to identify. By leveraging advanced analytics techniques, rail operators can forecast potential failures, predict maintenance needs, and optimize asset performance [2][5]. This shift from a reactive to a predictive approach enhances reliability, extends asset lifespan, and enables data-driven decision-making in rail maintenance and operations.

Overcoming Challenges and Embracing the Future

While the benefits of automation in predictive rail inspection are clear, the industry must also address certain challenges to ensure widespread adoption. Integrating new technologies into existing systems and ensuring the reliability of automated solutions are key considerations [3]. Rail operators must work closely with technology providers to develop robust and scalable solutions that seamlessly integrate with their operational frameworks. Overcoming these challenges will pave the way for a future where automated predictive inspection becomes the norm, driving continuous improvements in rail safety, efficiency, and asset management.

The role of automation in predictive rail inspection represents a transformative shift in the industry. By harnessing the power of advanced technologies, rail operators can enhance safety, increase inspection frequency and accuracy, optimize maintenance costs, and embrace a data-driven, proactive approach to asset management [2][3][5]. As the industry continues to evolve, embracing automation will be crucial for rail companies seeking to remain competitive, ensure the highest standards of safety, and deliver reliable services to their customers.

#RailAutomation #PredictiveInspection #RailSafety #AssetManagement

-> Original article and inspiration provided by International Railway Journal

-> Connect with one of our AI Strategists today at ReviewAgent.ai